Here at Print.Save.Repeat. we primarily use flexographic printing on our machines to print labels. From an outside perspective, though, what is flexographic printing? What does that type of printing mean and entail? In this blog post, we here at Print.Save.Repeat. hope to answer that question.

What is flexographic printing?

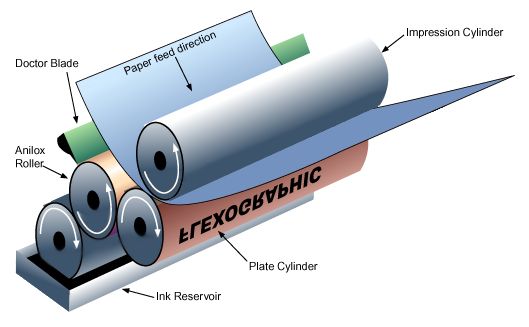

Also known as flexography or “flexo” printing, flexographic printing is a modern form of letterpress printing that uses flexible rubber or photopolymer plates to create a raised image that can be transferred onto a wide variety of materials. Without any of the professional terms, flexographic printing is essentially when a rubbery, flexible relief plate is bound around a printing cylinder and covered with sticky adhesive for labels. There are three stages to this kind of printing: plate making, mounting, and then the final printing.

The use of a plate cylinder (also known as an image cylinder) and an impression cylinder means that flexographic printing is a form of rotary printing, requiring a rotary printing press. While this process tends to use quick drying inks, UV inks can also be used to further speed up the drying process and prevent smudging.

Flexo label printing is capable of full color prints, however each individual color will require its own type of color station. Flexographic presses range between two to eight color stations, each of which has its own ink fountain, fountain roller, plate cylinder, and impression cylinder. These color stations can be arranged in three different ways:

- A stack press will stack the stations vertically, providing easy to access to the substrate and allowing both sides to be printed

- Central impression presses arrange the stations in a circle around the impression cylinder, which produces high quality print but only on one side of the substrate.

- Finally, an in-line press places the stations horizontally, allowing thicker substrates to be printed on and, if a turnbar is used, allows both sides to be printed.

Great care needs to be taken when printing multiple colors because if any of the different plates are misaligned, the colors won’t align correctly in the final image, resulting in a defective misprint.

Why flexographic printing?

One of the benefits to this kind of printing is that it allows for longer and quicker prints, ensuring that we can fulfill our customers’ larger orders in the quickest and most efficient method. Additionally, the machinery and upkeep costs are notably lower than other kinds of printing, which gives our company the opportunity to offer the most cost-effective and fair prices to our valued customers. Flexo label printing, too, provides the ability to have nearly limitless customization options, meaning that regardless of what our customers request, we are able to supply with ease.

We hope this blog post has been a helpful resource informing you about flexographic printing, for further questions, concerns, or comments we encourage you to call us any time at 800-587-1173.