Pressure sensitive labels serve a variety of purposes in our daily lives. Depending on their function, a label's adhesive properties may vary significantly. In this article we'll take a look at three adhesion properties and how they affect the performance of your labels.

Peel

Peel is a term that is used to describe the amount of force required to separate a label from the surface it has been placed on. A label's peel is measured at a 90 degree angle and a 180 degree angle. Peel strength can actually build over time so this property is typically tested at a variety of time lengths - anything from a couple of minutes to a few days. You can "see" the effects of peel when it comes to removable and permanent labels. Removable labels will typically be low peel while permanent labels will have a higher peel strength.

Tack

Sometimes referred to as the "quick stick" of the label, tack is similar to peel in that it measures the force required to break the bond between a label and a surface. However, tack specifically measures the force required in relation to immediate application and removal. In other words, tack tells you if the initial label adhesion is strong enough to prevent your label from detaching from the surface it was placed on (this allows peel to grow over time).

Shear

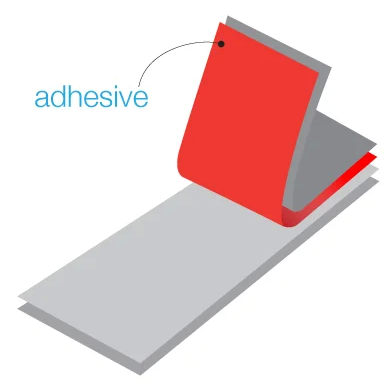

Shear is a measure of the cohesive strength of a label. When the shear properties are being tested a weight is hung from the end of a label that is partially attached to a surface. The longer it take the label to break free from the surface the greater the shear. Higher shear labels are great for joining two surfaces together like a box or container.

Looking for a label with specific requirements? Contact us! We'd love to help make your project a success.

Phone: 480-463-4548

Email: orders@printsaverepeat.com