Printing Terms: Finishing

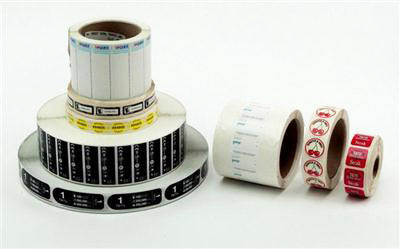

When shopping for label products, which are generally simple and straightforward, sometimes the precise language and specific terms can catch shoppers off-guard. Label finishes, for example, are traits that commonly differentiate products, and the distinctions between them are made usually without any explanation. So what does each finish mean? Which ones are right for your business? In this blog post we intend on answering these questions.

Here at Print.Save.Repeat. we offer three different kinds of label finishes – laminated, varnished, and UV coated. The following descriptions will help show you what each type is and which ones you may need for your business.

Laminated:

Laminate refers to the process by which layers are fused together via a web-like material, bonding two or more layers together (through heat, pressure, or adhesives). Essentially, Labels featuring a Laminate finish are covered in a film material that acts as a thick protective layer which makes the labels resistant against moisture, light exposure, abrasion, and other common erosive factors.

Varnished:

Varnish is a type of coating material made of a drying oil and a resin that are dissolved in a solvent. Varnishes form a clear film that is usually glossy, but may produce a satin or semi-gloss finish through the addition of certain flatting agents. The finish is applied during the manufacturing process or after printing and are either “over coated” (cover the entire surface) or “spot coated” (cover sections of the surface). In labelling, varnishes are most commonly used as a coating on face materials, but can also be used as a vehicle for ink where they help to produce a glossy print finish. Varnish coatings enhance the appearance of a face material and provide a cover that is notably smooth. Using a varnish finish with labels typically will cost less than laminate or UV labels, too, however in comparison they are the least durable and therefore best used for indoor or simple labeling.

UV Coated:

UV coating is a type of varnish that is cured by exposure to UV light. UV coatings usually have a degree of solid content and can be produced as 100% solids that are applied as a thin film, dying almost instantly when exposed to UV light. They can be applied during the manufacturing process or after printing and are either “over coated” (cover the entire surface) or “spot coated” (cover sections of the surface). It should be noted that while these varnishes are cured by UV light, they do not offer protection against the harmful effects of exposure to UV light. In labeling, these coatings enhance the surface adding a gloss finish (although flatting agents can be added to produce semi-gloss or matte finishes) and a protective coating. While UV coating is often the most expensive label finish, it is the longest lasting and most glossy.

The specifics of label finishing are important to understand for your printing needs - we hope that the information from this blog post is a good resource for your business. For any further questions, concerns, or comments, we encourage you to call us at 800-587-1173 and we will be sure to give you an answer. To purchase any label or toner product, we are confident you will find everything that you are looking for here at Print.Save.Repeat.